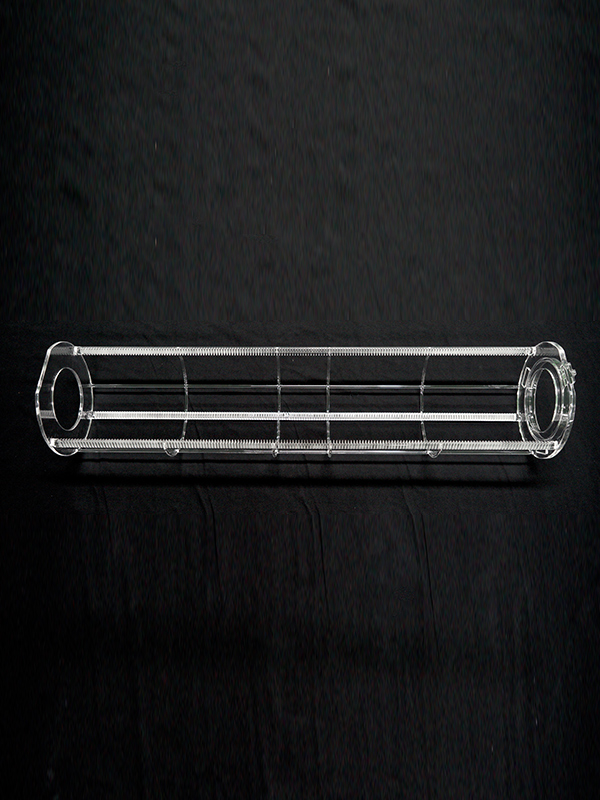

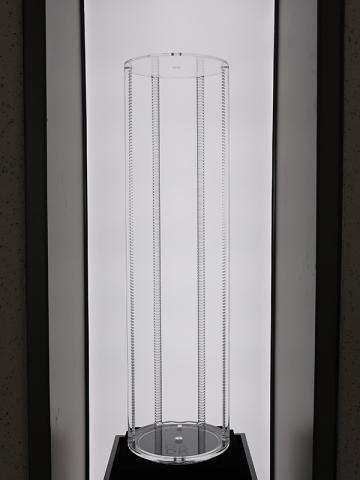

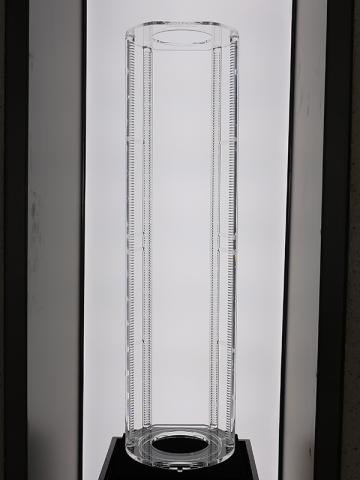

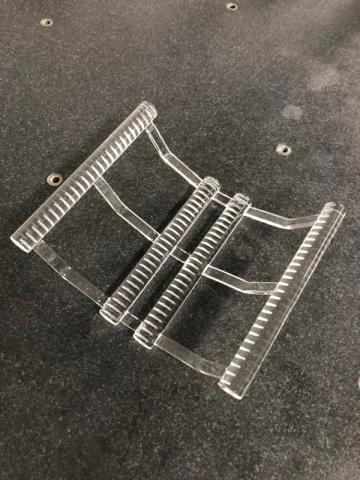

Quartz Boat

Name:

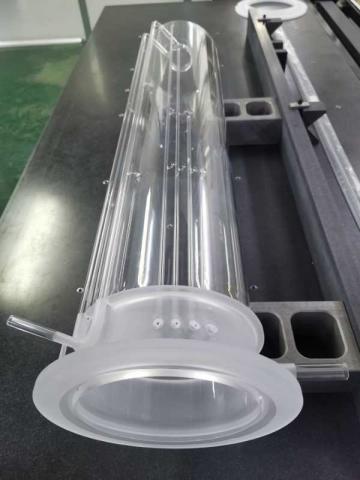

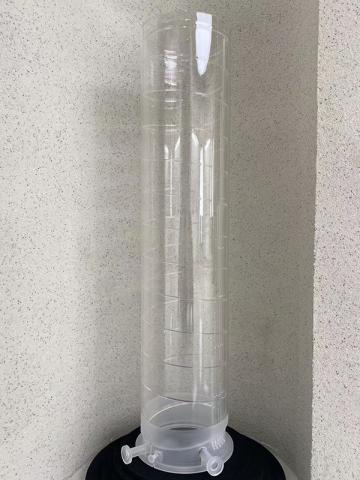

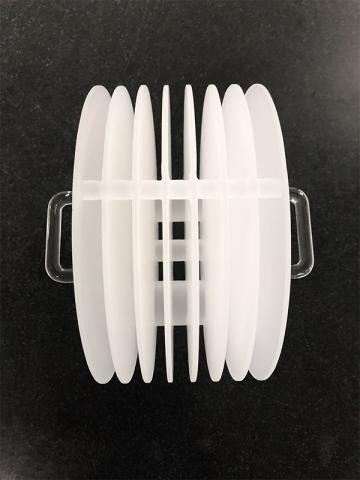

8-inch Vertical Furnace Quartz Wafer Boat

Function & Application:

The vertical quartz boat is placed upright inside the quartz tube and serves as a carrier for wafer transport, handling, and processing. Wafers are loaded onto the quartz boat, which is then placed into the furnace tube for batch manufacturing. It is used in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The vertical furnace quartz wafer boat is purpose-built for handling larger wafer sizes in advanced thermal processing applications such as diffusion, oxidation, and LPCVD. Crafted from high-purity quartz glass, it offers outstanding thermal stability, chemical resistance, and structural integrity in high-temperature furnace environments.

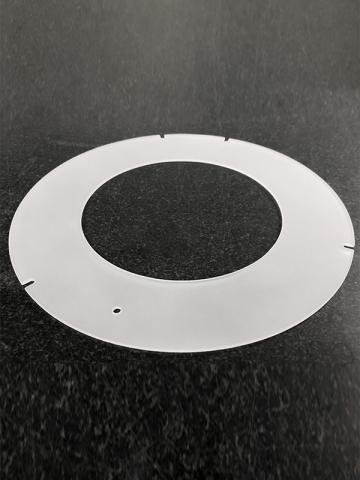

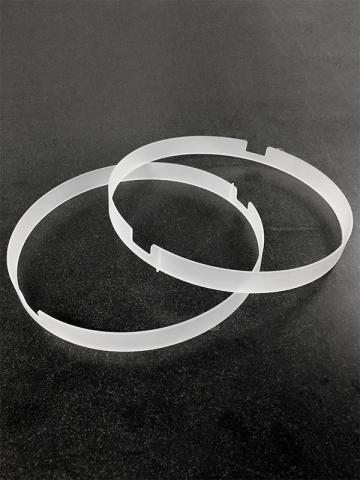

Engineered to support 8 inch (200 mm) wafers with precise spacing and alignment, this quartz boat ensures uniform heat distribution and optimized gas flow across the entire wafer surface. Its smooth, low-contamination surface and dimensional precision make it ideal for cleanroom-class semiconductor fabrication. Compatible with both vertical and horizontal furnace systems, the 8 inch quartz glass boat plays a critical role in maintaining process consistency, yield stability, and overall equipment efficiency in modern wafer manufacturing lines.

Durability and Thermal Shock Resistance of Quartz Wafer Boats

Quartz wafer boats used in vertical furnaces must withstand extreme process conditions, including rapid heating, cooling, and repeated thermal cycling. Their durability directly impacts wafer yield, equipment uptime, and overall production cost. High-purity fused quartz offers unique advantages in this regard: it resists devitrification, maintains structural stability at temperatures above 1,000 °C, and minimizes particle generation that could contaminate wafers.

One of the key performance indicators is thermal shock resistance. A well-engineered quartz wafer boat can endure sudden temperature changes without cracking or warping. This property ensures stable wafer positioning and consistent gas flow during oxidation, diffusion, or annealing processes.

To maximize lifetime, manufacturers focus on optimized geometry, smooth surface finishing, and strict control of quartz purity. Proper cleaning and handling are also essential to prevent micro-cracks, which are the most common cause of premature failure. By combining high-grade materials with precise fabrication, quartz wafer boats deliver long service life even under demanding semiconductor furnace conditions.