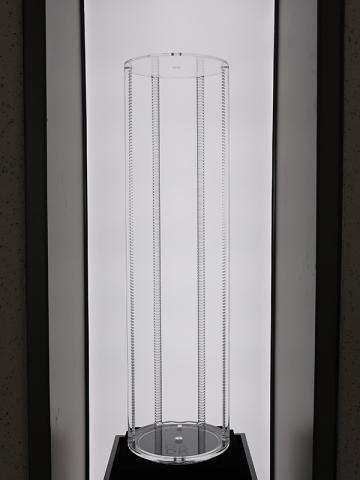

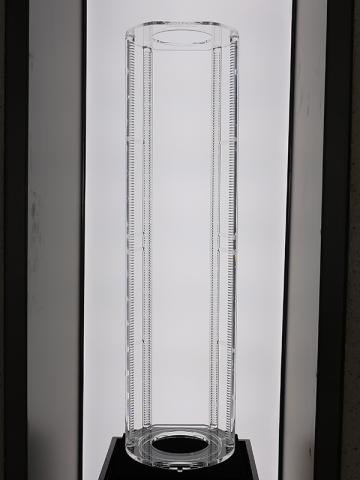

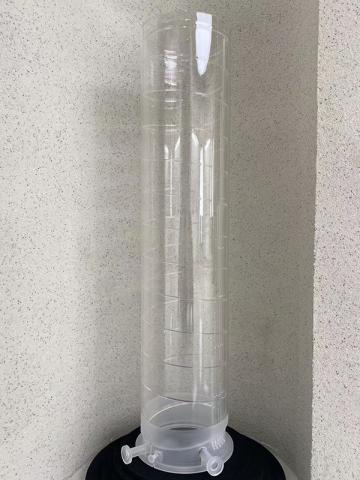

Quartz Process Tube

Name:

8-inch Quartz Process Tube

Function & Application:

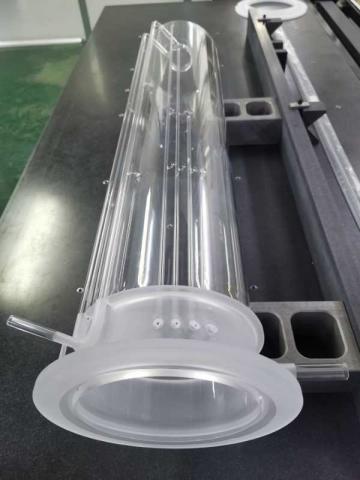

In semiconductor manufacturing, the quartz process tube serves as a core carrier for high-temperature processes, performing key roles such as enclosing a high-temperature environment, acting as a container for monocrystalline silicon growth, resisting corrosive gas erosion, and maintaining an ultra-pure environment. It is applied in wafer manufacturing processes including diffusion, oxidation, CVD deposition, material preparation and cleaning, plasma process protection, process monitoring, and gas control, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

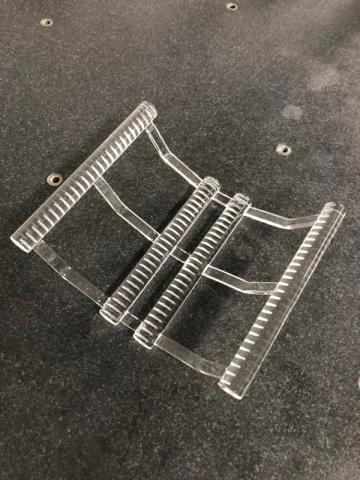

The quartz process tube is a vital component in high-temperature semiconductor and photovoltaic manufacturing equipment, designed to provide a contamination-free environment for wafer processing. Made from high-purity fused quartz, it delivers exceptional resistance to thermal shock, chemical corrosion, and mechanical stress.

With its precise dimensional control and smooth inner surface, the process tube ensures uniform gas flow and temperature distribution, critical for processes such as oxidation, diffusion, LPCVD, and annealing. Its structural stability under repeated thermal cycling guarantees long service life and consistent production quality. Suitable for both vertical and horizontal furnace systems, the 8 inch quartz process tube supports advanced 200 mm wafer fabrication lines by maintaining process integrity, yield consistency, and operational reliability.

Why Furnace Designers Prefer Quartz Process Tubes over Other Materials

1. Exceptional Thermal Stability

Quartz maintains structural integrity at extremely high temperatures, allowing consistent wafer processing without deformation or cracking.

2. Superior Chemical Resistance

Unlike metals that may corrode or react with process gases, quartz is chemically inert, ensuring minimal contamination in oxidation, diffusion, and CVD processes.

3. High Purity and Low Impurity Content

Fused quartz tubes have very low levels of impurities and bubbles, which is critical for preventing defects in sensitive semiconductor wafers.

4. Precise Dimensional Accuracy

Quartz tubes are manufactured with tight tolerances, allowing for consistent gas flow and uniform thermal distribution within the furnace.

5. Long-Term Durability

Quartz resists thermal shock better than metals or ceramics, reducing downtime and replacement costs in semiconductor fabs.

The combination of thermal stability, chemical inertness, high purity, and precise dimensions makes quartz process tubes the preferred choice for furnace designers. Selecting high-quality quartz tubes ensures improved wafer yield, uniformity, and reliable long-term operation.