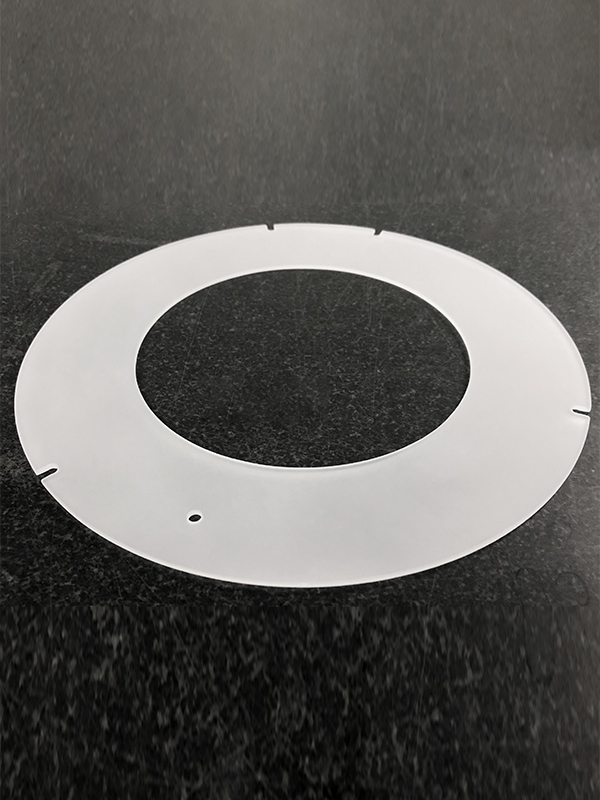

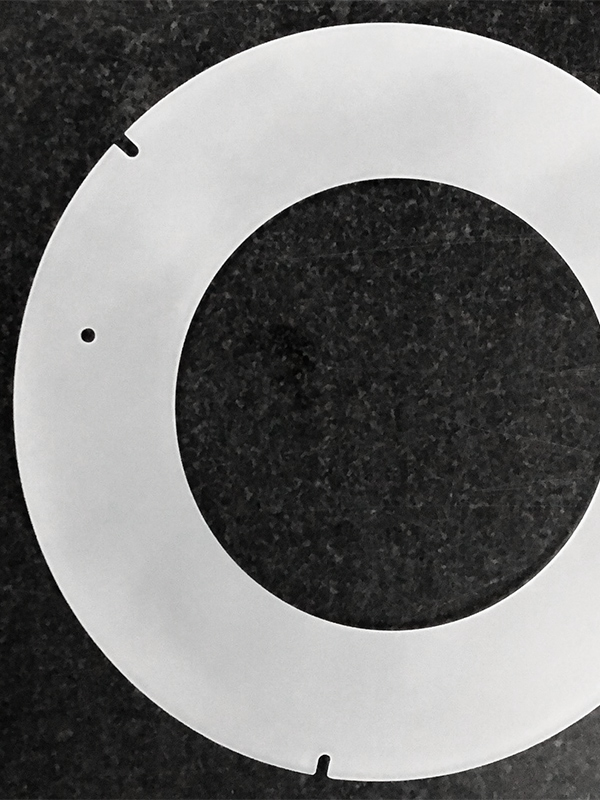

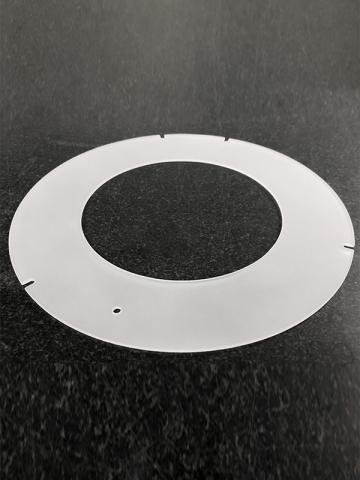

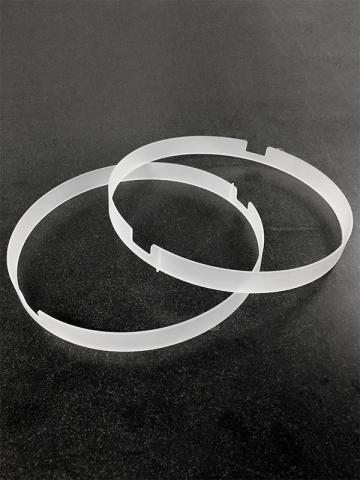

Quartz Ring

Name:

8-inch OP Quartz Ring

Function & Application:

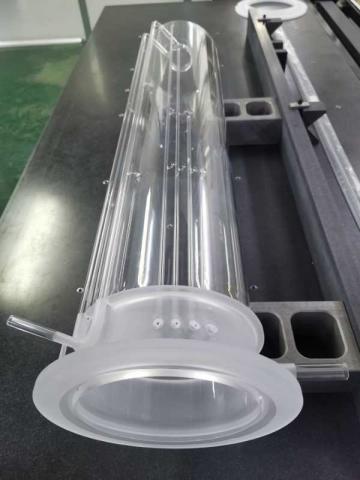

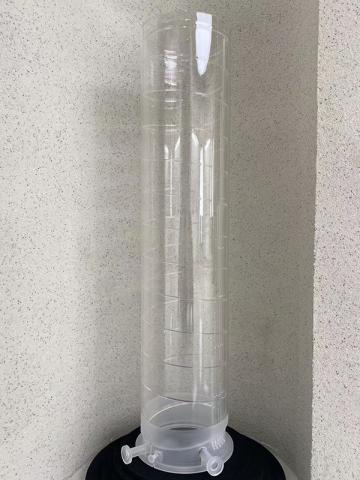

Acts as a protective component to prevent various contaminations during the etching manufacturing process, ensuring sealing and protection of the chamber. It is applied in wafer manufacturing etching processes, which are low-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

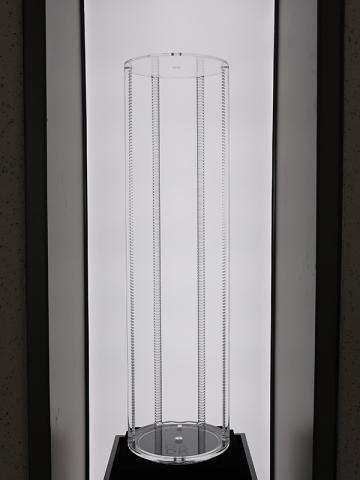

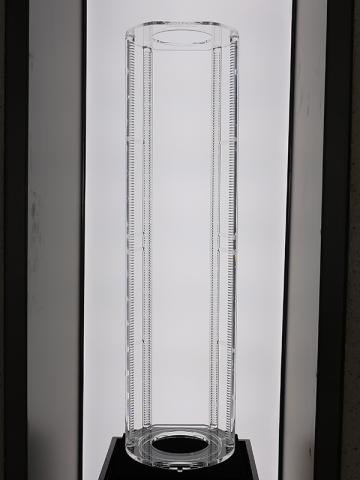

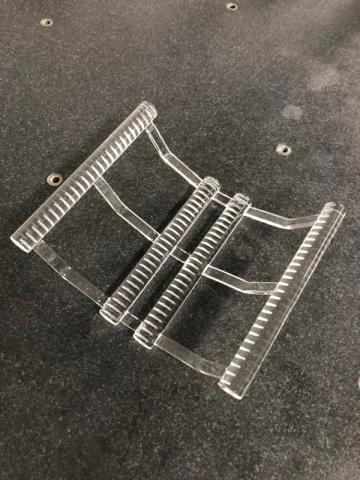

The OP Quartz Ring is a high-precision component crafted from ultra-pure fused silica, designed to provide reliable support, sealing, or spacing within semiconductor and photovoltaic processing systems. Known for its exceptional thermal stability, low thermal expansion, and outstanding chemical resistance, this ring withstands harsh processing environments and repeated thermal cycling.

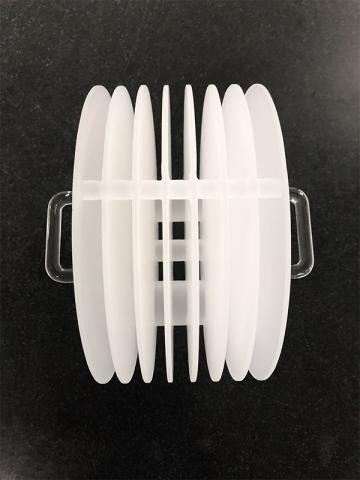

Its precise dimensions ensure optimal fit and alignment in furnace assemblies, contributing to uniform gas flow and temperature control during processes such as CVD, diffusion, and annealing. The fused silica glass ring helps maintain a contamination-free environment, critical for achieving consistent wafer quality and high process yields.

OP Quartz Rings vs. Standard Quartz Rings

OP (Opaque) Quartz Rings are specialized components designed for high-temperature semiconductor processes where thermal insulation and reduced radiation effects are critical. Compared to standard quartz rings, OP Quartz Rings offer higher opacity, better thermal shielding, and lower light transmission, helping to maintain stable furnace conditions and minimize wafer contamination.

Standard quartz rings, while chemically pure and thermally stable, transmit more thermal radiation and are better suited for general-purpose applications where insulation is less critical. Choosing between OP and standard quartz rings depends on process requirements, furnace design, and the need for thermal uniformity and wafer protection.

Key Points:

- OP rings: opaque, superior thermal insulation, ideal for sensitive processes.

- Standard rings: transparent, general-purpose, cost-effective.

- Selection impacts wafer uniformity, contamination control, and process stability.