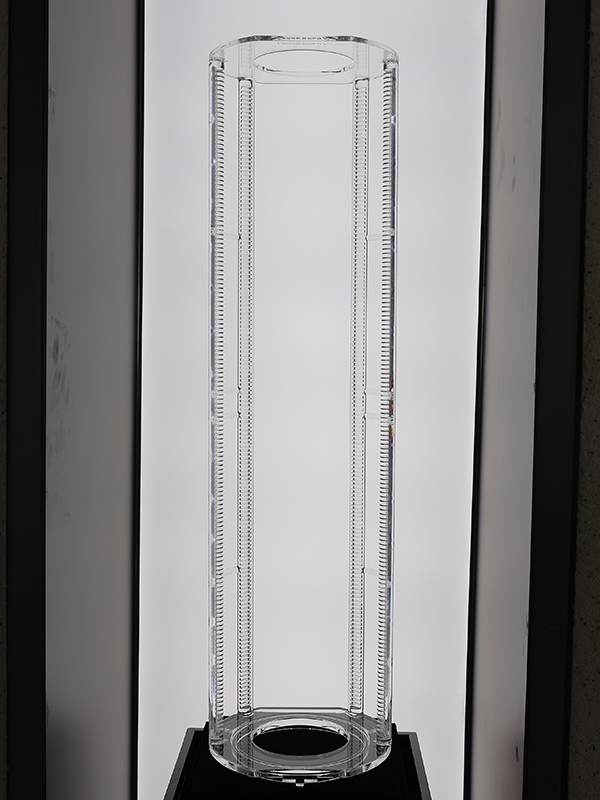

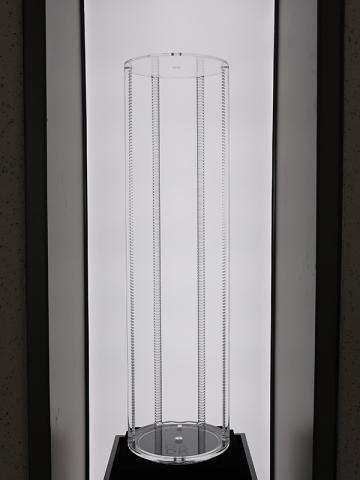

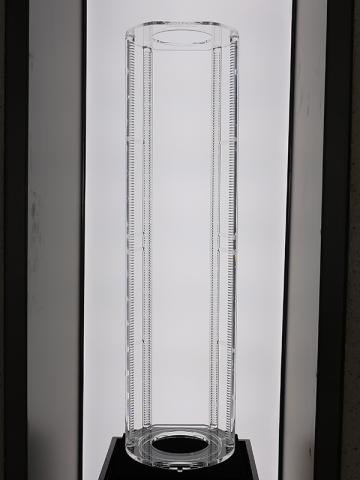

Quartz Boat

Name:

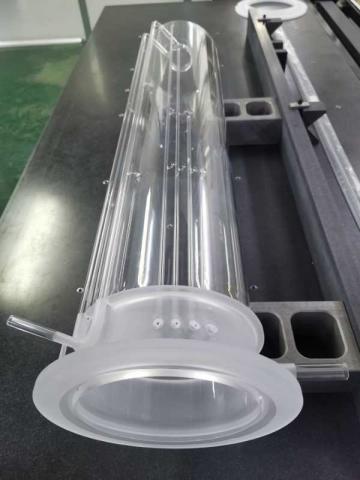

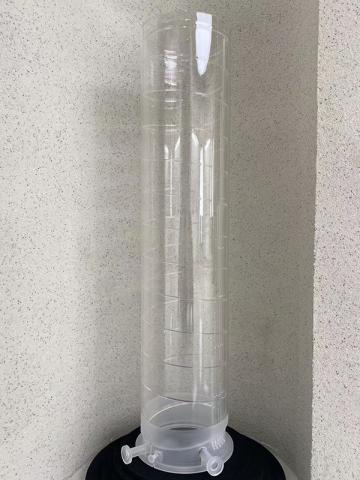

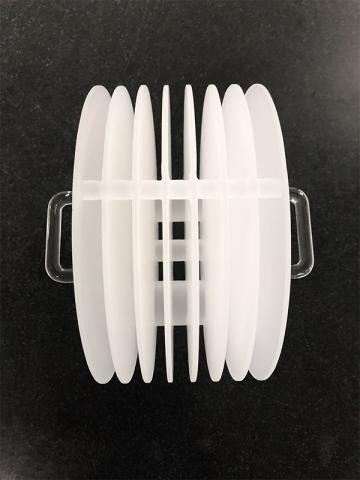

8-inch Vertical Furnace Quartz Wafer Boat

Function & Application:

The vertical quartz boat is vertically placed inside the quartz tube and serves as a carrier for wafer transport, handling, and processing. Wafers are placed onto the quartz boat and then loaded into the furnace tube for batch manufacturing. It is applied in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

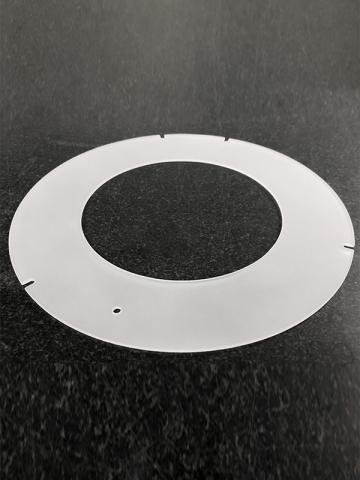

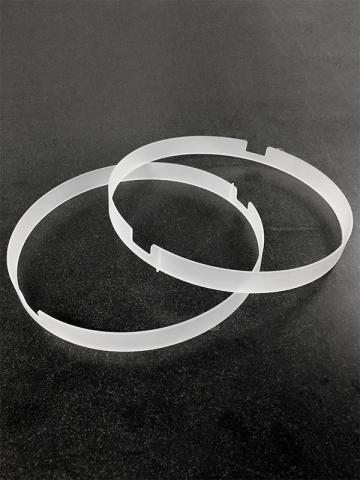

The vertical quartz boat is designed to securely hold 200 mm wafers in vertical furnace systems used for high-temperature processes such as oxidation, diffusion, and LPCVD. Manufactured from high-purity fused quartz, it offers exceptional resistance to thermal shock, chemical corrosion, and mechanical deformation.

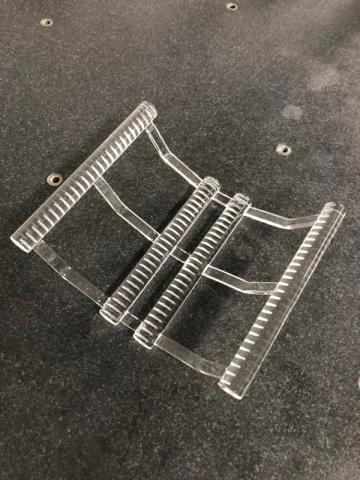

Engineered for vertical loading configurations, this quartz boat ensures uniform wafer spacing and stable alignment, promoting even gas distribution and consistent thermal exposure across all wafer surfaces. Its rigid construction maintains integrity under thermal cycling, reducing contamination risks and enhancing process repeatability.

High-Purity Vertical Quartz Boats: Key to Consistent Wafer Quality

High-purity vertical quartz boats are essential components in semiconductor manufacturing, designed to transport and support silicon wafers during high-temperature processes such as diffusion, oxidation, and CVD deposition. Constructed from ultra-pure quartz, these boats minimize contamination risks, ensuring that wafers remain pristine throughout processing.

The vertical design promotes uniform gas flow and heat distribution across all wafers, reducing temperature gradients and improving process consistency. Smooth, low-impurity surfaces prevent particle generation and help maintain cleanroom standards, directly contributing to higher wafer yield and reliable device performance.

Durable and thermally stable, high-purity vertical quartz boats withstand repeated thermal cycling without deformation or cracking. By selecting these precision-engineered carriers, semiconductor fabs and research facilities can achieve more predictable results, enhance throughput, and maintain strict quality control in demanding manufacturing environments.